Developments of Turkmen scientists: strength of steel, improved bitumen and cement

Development of technological bases of integrated processing of mineral hydro mineral and hydrocarbon materials is a priority direction of studies of personnel of the Institute of Chemistry of the Academy of Sciences of Turkmenistan. Innovative solutions are suggested by the laboratories of the institute, which work on contractual terms with facilities of the leading branches of the economy of the country.

Ferrosilicon – 41 – alloy from local raw materials

Personnel of the laboratory of chemical production technology has developed the recipe of chemical mixture for improvement of strength of steel made at facilities of the Ministry of Industry and Construction Production. Ferrosilicon, the alloy of silicon and iron, was received by experimental methods from local materials at Türkmendemirönümleri Plant.

The tests have proven high strength indicators of the alloy. Specialists think that it can also be used as oxidizing and alloying additive for production of various types of steel like spring steel, corrosion and heat resistant steel.

Personnel of the laboratory of the Institute of Chemistry used local raw materials – quartz sand from Myane deposit in Kaahka district, tempered coke and graphite from Turkmenbashy Refinery Complex, iron chips and slag from metallurgic facility.

We have received material, which has required physical and chemical properties at low cost, - senior scientists of the laboratory G. Amannazarov says. – Turkmen ferrosilicon – 41 can be used in foundry and metallurgic industry, having replaced expensive import analogue. Nowadays, personnel of the lab works on increment of silicon content in the additive, which will improve the strength of steel.

Road bitumen: Reliable way to improve quality

Presentation of development of the Institute of Chemistry of the Academy of Sciences has been held at Turkmenbashy Refinery Complex. The method of improvement of properties of road bitumen made of oil with high wax content, which has been tested in the laboratory of chemical production technology, has been demonstrated to specialists.

It is difficult receive oil bitumen meeting high quality standards from such raw material. New technological methods, which allow extracting qualitative bonding materials from oil saturated with wax, had to be tested. The attention to this subject is closely related to the growth of requirements to operation characteristics of asphalt and concrete cover of roads caused by increment of transport flows.

Personnel of the institute has developed a technology of production of road bitumen by refining of tar in inert gas environment. Residual bitumen meeting high standards of viscosity, sensitivity to change of temperature, fragility, flexibility has been received during the test at laboratory installation.

Waxes and oils, which can also be used as a raw material for making of other production of oil refinery, are associated product during processing of tar. Specialists of the refinery included the technology suggested by scientists to the concept of development of the facility in coming years.

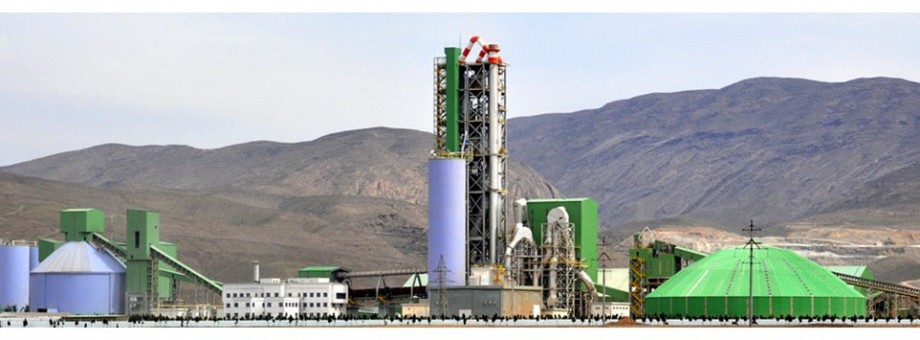

Basalt additives increased volumes and reduced cost of cement production

Application of active mineral additives developed by scientist of the Institute of Chemistry of the Academy of Sciences of Turkmenistan, Candidate of Chemical Sciences R. Nurberdiyev allowed increasing production of cement by 20 percent at the plants of the Ministry of Industry and Construction Production of Turkmenistan.

The State Intellectual Property Service of the Ministry of Economy and Financeshas recognized the work of the scientists and issues a patent to him.

According to the proposal of the specialist, crushed basalt porphyrites – local raw material produced at Ufra deposit in Balkan Region, started to be added to the mixture of clinker and gypsum. It allowed not only increasing production of this construction material but also improving its quality as well as reducing the cost for raw material, power, gas. Harmful emissions to the atmosphere have also been reduced.

Lebap Cement Plant, where tests of mineral additives have been carried out, received quality certificate for 400 – G20 – K cement. At present time, production personnel and scientists work on production of 500 – G20 – K cement.

Briquetted wild rue

Local chemists have developed the method of production of briquettes of dried wild rue. Steams and leaves of the wild rue contains number of alkaloids – complex compounds having exclusively big physiological activity and making healing effect on organism.

To receive briquettes, shredded grass is moisturized, mixed until homogeneous mass, which is shaped up at certain temperature and pressure. After cooling , received briquettes are sent to dryer where it is heated up until 90 degrees. The medicine is ready after two hours.

HABARLAR

HABARLAR